The Growth and Impact of Die Casting in Malaysia

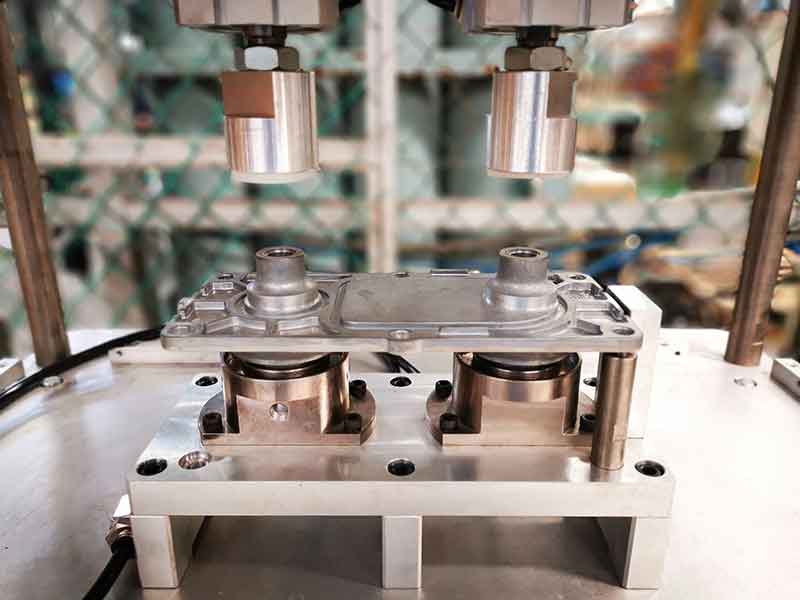

Diecasting plays a crucial role for Malaysia's manufacturing that contributes significantly to the production of high-quality metal components for various industries. The manufacturing process entails injecting the molten metal, usually zinc or aluminum, into molds under high pressure, allowing for creating precise and complicated shapes. Due to a rising demand for sturdy, light metal pieces, diecasting is gained importance in industries like electronics, automotive, and consumer goods. Malaysia's thriving diecasting industry is driven by technological advancements that are backed by skilled workforce and Malaysia's position as a strategic player in Southeast Asia, making it an essential player in the global supply chain.  Die-casting in Malaysia is well placed to cater to a variety of global markets thanks to its proximity to manufacturing centers in Asia. Automotive industry specifically is among the major consumers of die-cast components. It uses them to make engine parts in transmission systems, components for engine parts, as well as structural components. Malaysian companies have adapted to the demand for these parts by enhancing their production methods, focusing on quality and efficiency. High-tech machinery and precise tools have been implemented in die casting facilities throughout the country in order to satisfy the strict requirements of international markets. A growing use of aluminum and magnesium alloys in automobile components has enhanced Malaysia's position as a supplier of lightweight, performance parts. Automotive manufacturing is one of the major drivers for diecasting in Malaysia. Since automakers are moving toward lightweight, energy efficient vehicles The demand for lighter metallic components has increased. Diecast aluminum, renowned for its strength and light weight, is now a necessity for the production of parts like engines, transmission housings as well as structural parts. The diecasting industry in Malaysia has been able to adapt to these trends by investing in modernization technologies to permit the manufacturing of large quantities of sophisticated and durable parts for the automotive sector. This focus on innovation and precision has positioned Malaysia as the leading source of components made from diecast for automobile makers around the world, especially when the market shifts towards electric automobiles (EVs). Another important use of Diecasting Malaysia is in the electronic business, where precision as well as the reliability of components are crucial. Diecast parts are utilized to create a variety of electronic devices ranging from laptops, smartphones, household appliances and industrial equipment. Diecasting's ability to make complex shapes while maintaining tight tolerances makes it ideal to create intricate parts that are required for modern electronic devices. Since the demand for consumer electronics continues increase globally, Malaysia's diecasting sector is in a good position to profit from this growing demand. Utilizing advanced manufacturing techniques, such as high-pressure casting and computer-aided designs (CAD) is allowing Malaysian manufacturers to produce high-quality electronic parts that conform to the international standards. To generate extra details kindly check out www.senadiecasting.com.my/

Die-casting in Malaysia is well placed to cater to a variety of global markets thanks to its proximity to manufacturing centers in Asia. Automotive industry specifically is among the major consumers of die-cast components. It uses them to make engine parts in transmission systems, components for engine parts, as well as structural components. Malaysian companies have adapted to the demand for these parts by enhancing their production methods, focusing on quality and efficiency. High-tech machinery and precise tools have been implemented in die casting facilities throughout the country in order to satisfy the strict requirements of international markets. A growing use of aluminum and magnesium alloys in automobile components has enhanced Malaysia's position as a supplier of lightweight, performance parts. Automotive manufacturing is one of the major drivers for diecasting in Malaysia. Since automakers are moving toward lightweight, energy efficient vehicles The demand for lighter metallic components has increased. Diecast aluminum, renowned for its strength and light weight, is now a necessity for the production of parts like engines, transmission housings as well as structural parts. The diecasting industry in Malaysia has been able to adapt to these trends by investing in modernization technologies to permit the manufacturing of large quantities of sophisticated and durable parts for the automotive sector. This focus on innovation and precision has positioned Malaysia as the leading source of components made from diecast for automobile makers around the world, especially when the market shifts towards electric automobiles (EVs). Another important use of Diecasting Malaysia is in the electronic business, where precision as well as the reliability of components are crucial. Diecast parts are utilized to create a variety of electronic devices ranging from laptops, smartphones, household appliances and industrial equipment. Diecasting's ability to make complex shapes while maintaining tight tolerances makes it ideal to create intricate parts that are required for modern electronic devices. Since the demand for consumer electronics continues increase globally, Malaysia's diecasting sector is in a good position to profit from this growing demand. Utilizing advanced manufacturing techniques, such as high-pressure casting and computer-aided designs (CAD) is allowing Malaysian manufacturers to produce high-quality electronic parts that conform to the international standards. To generate extra details kindly check out www.senadiecasting.com.my/  In spite of its numerous advantages, the diecasting industry in Malaysia has many problems. The most urgent issues is the rising cost of raw materials, especially aluminum and zinc, which typically are utilized for diecasting. The fluctuations in the global price of metal can have a significant impact on profitability of diecasting operations. In addition, the industry has to tackle environmental issues related to energy consumption and waste generation. Numerous diecasting businesses in Malaysia are adopting greener practices by using recycled metals, and investing in energy efficient techniques, in order to minimize their carbon footprint. These initiatives are vital as the industry tries to reconcile the growth of its business with sustainability in an increasingly eco-conscious the world. Die casting in Malaysia is an incredibly growing business with a solid foundation in manufacturing precision. Malaysia's capability to manufacture quality parts for industries such as electronic and automotive as well as communications has established it as an essential player on the international market. With advancements in technology manufacturing methods that reduce costs and a strong focus on environmental sustainability, Malaysia's die casting manufacturing industry is well-positioned to satisfy the needs of the future. While the business continues to grow, the manufacturers from Malaysia will play a more significant role in providing the world with precision-engineered components, driving growth and innovation in diverse sectors.

In spite of its numerous advantages, the diecasting industry in Malaysia has many problems. The most urgent issues is the rising cost of raw materials, especially aluminum and zinc, which typically are utilized for diecasting. The fluctuations in the global price of metal can have a significant impact on profitability of diecasting operations. In addition, the industry has to tackle environmental issues related to energy consumption and waste generation. Numerous diecasting businesses in Malaysia are adopting greener practices by using recycled metals, and investing in energy efficient techniques, in order to minimize their carbon footprint. These initiatives are vital as the industry tries to reconcile the growth of its business with sustainability in an increasingly eco-conscious the world. Die casting in Malaysia is an incredibly growing business with a solid foundation in manufacturing precision. Malaysia's capability to manufacture quality parts for industries such as electronic and automotive as well as communications has established it as an essential player on the international market. With advancements in technology manufacturing methods that reduce costs and a strong focus on environmental sustainability, Malaysia's die casting manufacturing industry is well-positioned to satisfy the needs of the future. While the business continues to grow, the manufacturers from Malaysia will play a more significant role in providing the world with precision-engineered components, driving growth and innovation in diverse sectors.